In the manufacturing and industrial world, the demand for precision, efficiency, and cost-effectiveness has never been greater. Among the technologies that contribute significantly to meeting these demands is Repmold. The term often appears in conversations about mold-making, production design, prototyping, and customized fabrication. It stands as an innovative approach that merges repeatability and mold-based production methods to create a reliable solution for industries ranging from automotive and aerospace to consumer goods and healthcare.

This article takes a deep dive into the concept of Repmold, exploring its definition, underlying principles, historical evolution, processes, applications, benefits, challenges, and its place in modern manufacturing ecosystems. By the end, readers will gain a full understanding of what Repmold is, why it matters, and how it can shape the future of production technology.

What is Repmold?

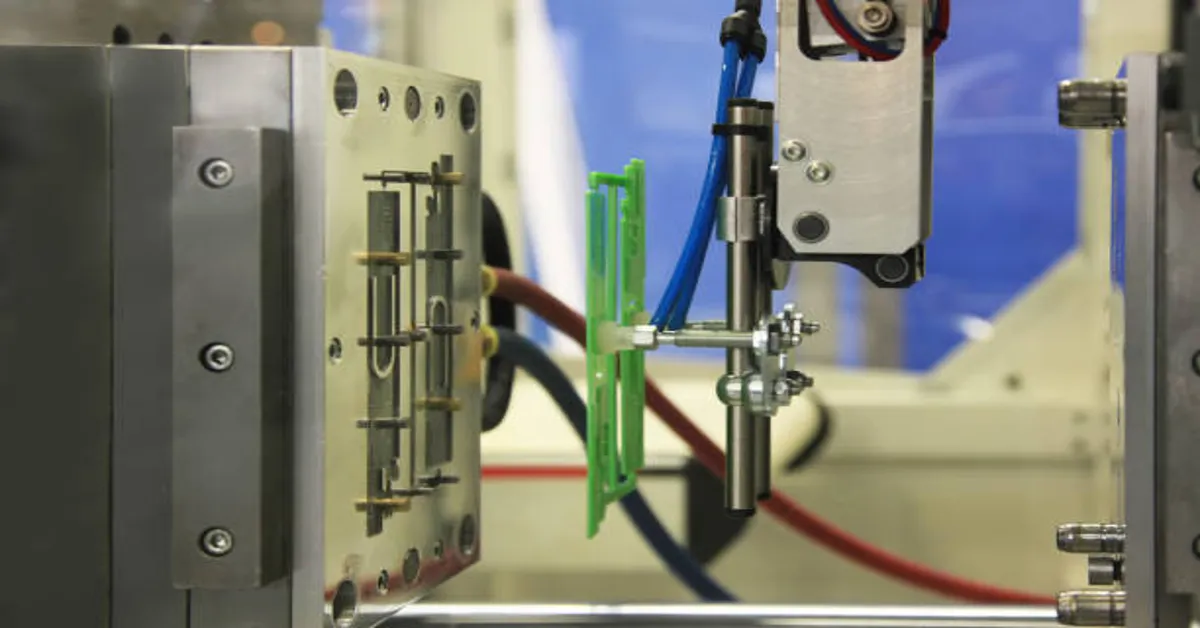

Repmold is a specialized mold-making and replication technology that allows for precise duplication of components through reusable mold systems. It combines the principles of molding with repeatability—hence the prefix “rep”—to ensure that multiple identical parts can be produced with consistent quality.

Unlike conventional one-off mold systems that are designed for limited use, Repmold focuses on durability, adaptability, and extended lifecycle. In other words, the process emphasizes not only producing a part once but also replicating it accurately multiple times while maintaining structural integrity, surface finish, and dimensional accuracy.

Historical Background of Repmold

The concept of molding itself dates back thousands of years, with clay, stone, and metal molds used by early civilizations for crafting tools, jewelry, and artifacts. However, the evolution of Repmold-style practices came during the industrial revolution when mass production became the norm.

In the mid-20th century, as plastics gained widespread popularity, manufacturers sought efficient systems to mass-produce plastic components for consumer products, medical devices, and automotive parts. Traditional molds were expensive and often limited to specific product lines. This spurred the development of more adaptable mold systems that could be reused and reconfigured—eventually forming the foundation of what we now refer to as Repmold.

Modern Rep mold technologies incorporate advanced materials like high-strength steels, composite mold shells, and even additive manufacturing techniques for mold inserts. This fusion of old principles and modern innovations enables Rep mold to be both flexible and robust in addressing today’s industrial demands.

Core Principles of Repmold

Rep mold technology is built upon several key principles that distinguish it from traditional mold-making:

- Repeatability – The ability to consistently replicate the same part multiple times without quality degradation.

- Durability – Mold systems are designed to endure stress, pressure, and repeated usage.

- Precision – High dimensional accuracy ensures uniformity across all produced parts.

- Adaptability – Molds can be reconfigured or slightly modified to accommodate product updates or new designs.

- Efficiency – Reduced cycle times and cost-effectiveness in mass production.

How Repmold Works: The Process Explained

The Rep mold process involves several stages, each of which plays a vital role in ensuring accuracy and longevity of the mold. Below is a breakdown of the typical workflow:

1. Design Phase

- Engineers create 3D models of the product using CAD software.

- Critical aspects like shrinkage, material flow, and stress points are considered.

2. Mold Fabrication

- High-strength materials such as hardened tool steel, aluminum alloys, or reinforced composites are used.

- CNC machining, EDM (Electrical Discharge Machining), or additive manufacturing may be employed.

3. Surface Treatment

- To ensure smooth ejection and longevity, surface coatings like PVD (Physical Vapor Deposition) or nitriding may be applied.

4. Trial Runs

- Initial samples are produced and measured for accuracy.

- Adjustments are made to eliminate errors and achieve tight tolerances.

5. Production Cycle

- The mold enters full-scale production, replicating thousands or even millions of parts.

- Continuous monitoring ensures consistency.

6. Maintenance

- Molds undergo regular inspections and minor refurbishments to extend life.

Materials Used in Repmold Systems

| Material | Properties | Common Use |

|---|---|---|

| Tool Steel | High hardness, wear resistance, long lifespan | Automotive & aerospace molds |

| Aluminum Alloys | Lightweight, good thermal conductivity, moderate strength | Prototyping and short production runs |

| Epoxy Resins | Cost-effective, easy to shape, lower durability | Low-volume production and prototyping |

| Composite Materials | High strength-to-weight ratio, corrosion resistance | Specialized industries (medical, marine) |

| Copper Alloys | Excellent thermal conductivity, used in mold inserts for heat transfer control | Injection molding inserts |

Applications of Repmold

Rep mold finds applications across numerous industries due to its versatility and cost-effectiveness.

- Automotive Industry – For producing dashboards, bumpers, interior panels, and under-the-hood components.

- Aerospace – Used for lightweight composite parts, ducting systems, and safety equipment.

- Consumer Electronics – Enclosures, buttons, and precision parts for gadgets.

- Healthcare & Medical Devices – Syringes, prosthetic components, casings for medical equipment.

- Packaging Industry – Caps, closures, containers, and bottles.

- Construction – Fixtures, fittings, and modular elements.

- Sports Equipment – Helmets, protective gear, and performance components.

Advantages of Repmold

Rep mold offers several significant benefits over traditional mold-making and production methods.

- Consistency in Quality – Every replicated unit matches the original design.

- Cost Efficiency – Long mold life reduces replacement costs.

- Flexibility – Adapts to design modifications with minimal downtime.

- Scalability – Ideal for both small and large production runs.

- Reduced Waste – Efficient use of raw materials minimizes scrap.

- Faster Production Cycles – Optimized designs enable quick turnaround.

Challenges and Limitations of Repmold

Despite its advantages, Rep mold is not without challenges:

- High Initial Cost – Designing and fabricating durable molds can be expensive.

- Complex Maintenance – Precision molds require regular care and specialized knowledge.

- Material Constraints – Not all materials are compatible with every mold type.

- Design Limitations – Extremely intricate designs may require hybrid manufacturing solutions.

Repmold vs Traditional Mold-Making

| Aspect | Repmold | Traditional Mold-Making |

|---|---|---|

| Cost Efficiency | Higher upfront but lower long-term costs | Lower upfront but higher replacement costs |

| Durability | Designed for repeated long-term use | Often wears down faster |

| Adaptability | Easier to modify or reconfigure | Difficult to alter once built |

| Applications | Ideal for mass production and prototyping | More limited in scalability |

| Consistency | Extremely high repeatability and accuracy | Variable, depends on operator skill |

Future of Repmold Technology

The future of Rep mold is tied to advancements in digital manufacturing, materials science, and sustainability.

- Integration with 3D Printing – Additive manufacturing will enable rapid mold insert replacement.

- Smart Molds – Incorporation of sensors for monitoring pressure, heat, and wear in real-time.

- Sustainable Materials – Biodegradable resins and recycled composites will reduce environmental footprint.

- Automation – AI-driven monitoring systems will enhance efficiency and reduce human error.

- Global Expansion – Emerging markets will adopt Rep mold to drive low-cost mass production.

Conclusion

Repmold is more than just a mold-making technique—it is a philosophy of repeatability, efficiency, and precision in manufacturing. It serves as a bridge between traditional mold-making and modern demands for flexibility and scalability. Whether in the automotive sector, healthcare, electronics, or packaging, Rep mold demonstrates its versatility and relevance.

As industries continue to move toward automation, sustainability, and digital transformation, Rep mold will play a crucial role in shaping the way products are designed, replicated, and delivered to global markets.

FAQs

Q1: What does Repmold mean?

Repmold refers to a mold-making and replication technology that emphasizes repeatability, precision, and efficiency for mass production.

Q2: How is Repmold different from traditional molding?

Unlike traditional molds, Repmold systems are built for durability, adaptability, and cost efficiency over long production cycles.

Q3: Which industries benefit the most from Repmold?

Repmold is widely used in automotive, aerospace, healthcare, packaging, consumer electronics, and sports equipment manufacturing.

Q4: What materials are commonly used in Repmold systems?

Materials such as tool steel, aluminum alloys, epoxy resins, composite materials, and copper alloys are frequently used.

Q5: What is the future of Repmold technology?

Future trends include smart mold integration, sustainable materials, AI-driven automation, and hybrid solutions with 3D printing.