Micro cellular rubber is a specialized class of synthetic elastomeric material engineered with a fine network of closed or semi-closed cells that impart unique properties such as lightweight construction, compressibility, resilience, and excellent thermal as well as acoustic insulation. Unlike conventional solid rubber, which has a dense and continuous structure, micro cellular rubber integrates millions of tiny air-filled cells distributed uniformly throughout its matrix. This structure allows the material to achieve high functionality across multiple industries while maintaining durability, flexibility, and stability under various conditions.

The demand for such advanced rubber materials has grown significantly in modern engineering, transportation, consumer goods, healthcare, and electronic applications, largely due to their ability to combine the essential qualities of rubber with added performance attributes. In this article, we will explore the science behind micro cellular rubber, its manufacturing processes, distinct features, advantages, applications, testing methods, and future prospects.

Understanding Micro Cellular Rubber

Cellular Structure

The term “micro cellular” refers to the small-sized pores or bubbles formed during the foaming process of rubber manufacturing. These cells are typically less than 200 microns in diameter and are evenly distributed throughout the material. Depending on design requirements, manufacturers can produce either open-cell micro cellular rubbers (where cells are interconnected) or closed-cell types (where each bubble remains sealed and isolated).

- Open-Cell Micro Cellular Rubber: Allows airflow and is suitable for cushioning and shock absorption.

- Closed-Cell Micro Cellular Rubber: Provides better water, gas, and chemical resistance, making it suitable for sealing and insulation.

Base Materials

Micro cellular rubbers can be manufactured from various elastomeric bases such as:

- EPDM (Ethylene Propylene Diene Monomer) – Excellent weather and ozone resistance.

- Neoprene – Balanced mechanical and chemical resistance properties.

- Nitrile Rubber (NBR) – Superior oil and fuel resistance.

- Silicone Rubber – Wide temperature stability and biocompatibility.

- Polyurethane (PU) – High abrasion resistance and resilience.

Each base material brings different advantages depending on the intended use.

Manufacturing Process of Micro Cellular Rubber

1. Compounding

The process begins with the preparation of a rubber compound. Base polymer, fillers, cross-linking agents, foaming agents, pigments, and stabilizers are mixed in a specific proportion to form a homogenous blend.

2. Foaming

A blowing agent (either chemical or physical) is introduced into the compound. Under heat and pressure, this agent decomposes or expands, generating gas bubbles that create the cellular structure.

- Chemical blowing agents release gases such as nitrogen or carbon dioxide during thermal decomposition.

- Physical blowing agents involve liquids with low boiling points that vaporize under heat.

3. Vulcanization

The foamed compound is subjected to controlled curing, also known as vulcanization, which enhances elasticity, tensile strength, and stability. Sulfur, peroxides, or other curing agents help form cross-links between polymer chains.

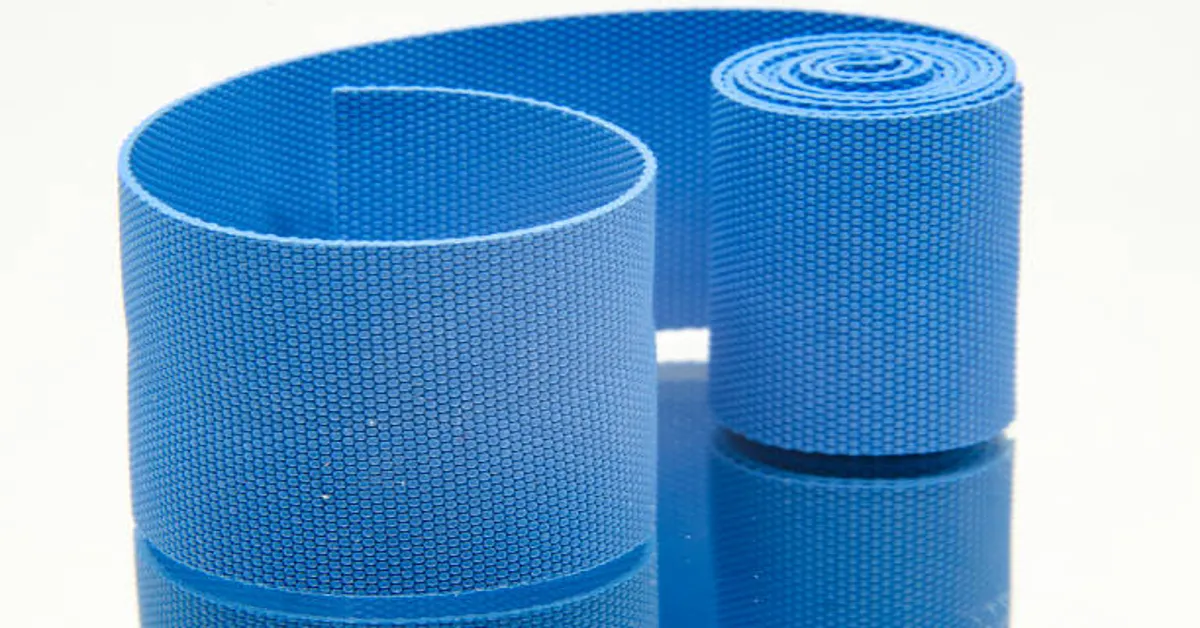

4. Shaping and Cutting

Once cured, the micro cellular rubber is shaped into sheets, rolls, or molded parts. Advanced CNC cutting or waterjet techniques are employed to achieve precise dimensions and tolerance levels.

5. Surface Treatment (Optional)

For enhanced adhesion or bonding, surface treatments such as lamination with adhesive films or coatings may be applied.

Physical and Mechanical Properties

| Property | Typical Range/Characteristic |

|---|---|

| Density | 0.2 – 0.9 g/cm³ |

| Compression Set Resistance | High (retains shape after repeated compression) |

| Tensile Strength | 0.5 – 5 MPa (depending on base material) |

| Elongation at Break | 100 – 400% |

| Hardness (Shore A or 00 scale) | Very soft to moderately hard |

| Thermal Conductivity | Low (excellent insulation) |

| Water Absorption (Closed Cell) | Minimal |

| Temperature Range | -50°C to +200°C (varies with material type) |

These properties make micro cellular rubber versatile for both structural and cushioning roles.

Advantages of Micro Cellular Rubber

- Lightweight and Flexible: Its cellular structure reduces weight without compromising strength.

- Excellent Sealing Ability: Closed-cell variants offer superior resistance against water, air, dust, and gases.

- Vibration and Shock Absorption: Provides damping effect for machinery, vehicles, and electronic devices.

- Thermal and Acoustic Insulation: Prevents heat transfer and reduces noise in automotive and construction uses.

- Chemical Resistance: Depending on base polymer, it resists oils, fuels, acids, and solvents.

- Durability: Resists compression set, ensuring long-term reliability in gaskets and seals.

- Customizability: Available in different hardness levels, thicknesses, and surface treatments.

Applications of Micro Cellular Rubber

Automotive Industry

- Weather Stripping & Seals: Prevents water, dust, and air leakage.

- NVH (Noise, Vibration, Harshness) Components: Reduces cabin noise and vibration.

- Gaskets for Engines and Fuel Systems: Ensures leak-proof performance under temperature fluctuations.

Construction and Infrastructure

- Expansion Joint Fillers: Accommodates structural movement while preventing seepage.

- Thermal Insulation: Used in HVAC ducting and building panels.

- Soundproofing Materials: Incorporated into walls and flooring.

Electronics and Electrical Applications

- Cushioning of Circuit Boards: Protects against vibration and impact.

- Seals for Enclosures: Maintains water and dust ingress protection (IP-rated devices).

- Thermal Pads: Silicone-based micro cellular rubbers used in heat management.

Medical and Healthcare

- Medical Device Seals: Biocompatible silicone micro cellular rubber used for gaskets.

- Orthopedic Supports: Lightweight padding for braces and prosthetics.

- Cushioning in Equipment: Shock-absorbing layers in sensitive medical instruments.

Consumer Goods

- Footwear Cushioning: Lightweight midsoles and insoles.

- Sports Equipment: Shock-absorbing grips and protective gear.

- Household Appliances: Noise and vibration reduction in washing machines or blenders.

Comparison with Other Materials

| Feature | Micro Cellular Rubber | Solid Rubber | Foam Plastics |

|---|---|---|---|

| Density | Low to medium | High | Very low |

| Elasticity | High | Very high | Medium |

| Sealing Capability | Excellent (closed-cell type) | High | Low to medium |

| Durability | High | High | Lower |

| Thermal/Acoustic Insul. | Excellent | Moderate | Excellent |

| Cost | Moderate | Moderate | Low |

Testing and Quality Standards

Micro cellular rubber undergoes rigorous testing before being approved for industrial or consumer applications. Some common testing parameters include:

- Density Measurement – Ensures uniform cellular structure.

- Compression Set Test – Determines ability to recover after load removal.

- Flammability Resistance – Compliance with UL94 standards.

- Tensile and Elongation Tests – Assess mechanical strength.

- Thermal Cycling – Evaluates performance under repeated heating and cooling.

- Aging Resistance – Exposure to ozone, UV, and humidity to predict service life.

Compliance with international standards such as ASTM D1056 (for cellular rubbers) is often required.

Environmental and Sustainability Aspects

Micro cellular rubber manufacturers are increasingly adopting eco-friendly practices, including:

- Using non-toxic blowing agents instead of ozone-depleting chemicals.

- Recycling production scrap into secondary products.

- Developing bio-based rubbers from renewable resources such as natural rubber latex.

- Enhancing durability to reduce replacement frequency, thereby minimizing waste.

Future Trends

The future of micro cellular rubber looks promising, with innovations in:

- Smart Rubber Materials: Incorporating sensors into cellular rubber for health monitoring and industrial IoT applications.

- Lightweight Automotive Solutions: Further reducing vehicle weight for better fuel efficiency and EV performance.

- Medical-Grade Innovations: Silicone micro cellular rubbers tailored for implants and biocompatible devices.

- Sustainable Manufacturing: Shift toward bio-elastomers and carbon-neutral production processes.

Conclusion

Micro cellular rubber stands as a remarkable material bridging the gap between conventional rubber and advanced engineered foams. Its combination of resilience, insulation, sealing ability, and lightweight properties make it indispensable across diverse industries such as automotive, electronics, construction, and healthcare. As technology advances, the scope of applications for micro cellular rubber will expand even further, particularly in areas that demand sustainability, performance, and multifunctionality. Understanding its properties and applications allows engineers, designers, and product developers to harness its full potential for innovative solutions.

ALSO READ: Classroom 15x: A Comprehensive Guide to the Next Era of Learning

FAQs

Q1. What is micro cellular rubber?

Micro cellular rubber is a lightweight elastomer with a fine network of air-filled cells that provide resilience, sealing ability, insulation, and flexibility for industrial and consumer applications.

Q2. How is micro cellular rubber different from solid rubber?

Unlike dense solid rubber, micro cellular rubber contains tiny cells that make it lighter, more compressible, and better at insulation and vibration damping.

Q3. Which industries use micro cellular rubber the most?

It is widely used in automotive seals, construction insulation, electronics protection, medical devices, and consumer products like footwear and appliances.

Q4. What are the advantages of closed-cell micro cellular rubber?

Closed-cell types offer superior water resistance, air sealing, chemical protection, and durability compared to open-cell variants.

Q5. Is micro cellular rubber environmentally sustainable?

Yes, many manufacturers are shifting toward eco-friendly blowing agents, recycling practices, and bio-based rubbers to enhance sustainability.